Blog 3

6th – 10th May

(Days 6-10)

Distance: 442km

Total Distance: 1011km

6th May

Keytah Farm

My visit to Keytah Farm was quite possibly the most interesting ‘rest day’ I’ve ever had off the bike during an expedition!

The visit to Keytah came about after I first found out about FibreTrace, a groundbreaking new innovation that enables manufactured cotton garments to be traced to the source, the grower. This facilitates transparency that in turn gives consumers the ability to choose ethically produced cotton clothing and protects cotton producers’ business…more on that later. I was impressed and contacted the owner/directors, David and Danielle Statham to find out more, noticing that their property, where FibreTrace is being pioneered, was on my route across Australia. David responded straight away and invited me to come and see what it is all about. I soon learned that FibreTrace is a part of a much bigger story, from visionary regenerative farming operations to processing the cotton (in Wathagar Gin) to developing FibreTrace technology to the finished traceable, carbon positive product, Good Earth Cotton.

The huge scale of the place and every operation that happens on it, is still difficult for me to fathom; even the front driveway is 11km long! Covering 65000 acres, Keytah is a sustainable cropping operation about 30km west of Moree. Nestled between the Gwydir and Mehi rivers, on a parcel of rich alluvial land, Keytah is world renowned for its innovative and efficient production techniques.

‘Keytah’ was purchased by David’s father’s Sundown Pastoral Company in 1984 when David was 17. Since then he has overseen its development from a productive cattle breeding property into one of the largest cotton producing properties in Australia, producing up to 78,000 bales a year at a rate of 7 to 15 bales per the hectare. Drastically improved yields and water efficiencies verify Keytah as one of the world’s most productive and water efficient cotton properties.

From the moment David started to talk about his work, the traits that stood out were his vision, passion and enthusiasm. He loves to be on the cutting edge of new ideas and develop them. Over the 37 years he has so far spent developing Keytah he says the key to his success as a manager is to employ the best people and look after them. All of the 29 full time employees live on the property, many have lived there for decades. Everywhere I looked, the place was clean and tidy, even the rubbish dump was organised into piles to be reused or repurposed. There seemed to be a lot of pride at all levels.

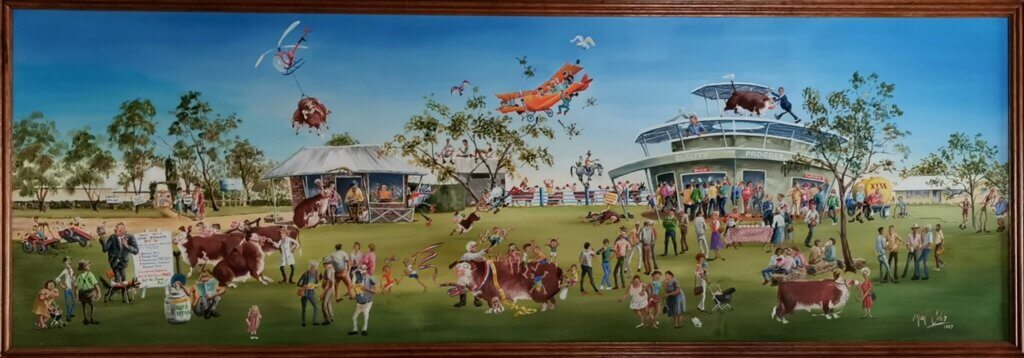

Our whirlwind tour began at the disused cattle trading amphitheatre and cattle feeding yards, where traders from around the world would bid for the prized cattle. Now relics consigned to Keytah’s history, many of the buildings are being used for the new business as workshops. These and all of the sheds on the property (many of industrial scale) are the product of Neil, his father’s shed-making business, Ranbuild, the success of which led to the development of the Sundown Pastoral Company. The nearby office isn’t large, as one might expect for the size of the business as most of the bookwork is done off the premises.

Every decision on the management is guided by science, its so hi-tech. Longitudinal studies over 20 years enable the agronomists and managers to map out the amount of carbon, nitrogen and water needs in the soil and analyse the effects of new techniques, pilot projects, the planting of different crops (other than cotton). The bigger picture is to understand the ecosystems around the farm. Sitting alongside the national conservation and designated World Heritage site Gwydir Wetlands, Keytah is also a showcase of how sustainable agriculture and environmental conservation can co-exist.

The tour continued, driving out to see some of the irrigated paddocks. Approximately 15,000 acres of the farm is under irrigation, Australia’s second largest irrigated single property (behind Cubby Station). When I had heard that the Mehi River had risen 10.5 metres flooding Moree seven weeks ago, I was worried how this might affect Keytah, but David said they have the ability to catch the water and store it in the irrigation lakes – the biggest one covers 1000 acres, and there are several others too. Water, David said, is the most valuable commodity of all. They must pay for it in the form of water licences (almost 1000 gigalitres each). These days, a water licence costs around $4million, though this is significantly more than when David started out. Keytah has 48 licences.

The property uses four different methods of irrigation – using channels of different types. The technology of the one that most impressed was the bank-less channel system. Each 350 acre (I think this size is correct) paddock is perfectly flat, made so with laser precision. Each paddock is set 30cm below the preceding one. Controllable from an iPad, the manager can control the exact amount of water released to flood a field so that it reaches all the way along the 60cm-wide furrows, all the way across the paddock (water is released from both sides). Once the correct amount reaches each plant, the manager simply switches the gates from the iPad to open the next set of gates and efficiently, the next paddock is watered. This method results in maximum efficiency to deliver water and nutrients and ultimately productivity.

If it wasn’t for the recent rains, the cotton harvest would have been in full swing. But still, the fields of almost pure white were impressive to look at. David’s team don’t simply rely on the rich alluvial black soil that has washed down from the volcanic ranges I had just crossed, they do much to build and develop the healthy soils, rich with earth worms and microorganisms.

The rest of the property is under a dryland rotational cropping system. In general they use a three-season rotation system; cotton is the summer crop and alternated with the winter crops such as wheat and other grains, and then thirdly, a legume such as chickpeas or faber beans. The legumes fix nitrogen back into the soil naturally. All stubble from the crops after harvest is left to break down and improve the soil.

Another very important technique is no tillage or ploughing using state of the art zero tillage precision planters which minimises disturbance of the soil. It’s the kind of technique that has been used by my family in Western Australia for years now to prevent soil erosion and maintain healthier soil. We also use a legume to improve soil fertility – lupins.

To find out more about the regenerative farming systems, check out – https://www.sundownpastoral.com.au/regenerative-farming/

I had questions about how the trapping of water affects the flow of water down the Darling River (the Murray-Darling basin is Australia’s biggest river system). David said that the Mehi River accounts for 1% of the Darling River’s flow while the Gwydir River on the other boundary of his property drains into the wetland. Sustainable and innovate farming practices have resulted in a yield increase of over 30% and water efficiency improvements of 235%. He said that the water licences for the whole system account for 22% of the flow of the Murray-Darling system.

Next was a visit to Wathagar Ginning where the cotton is separated from the seed and fibre. Again it is very high tech. A bale is processed in 55 seconds. To give some perspective, the lint from one 227kg cotton bale can produce 215 pairs of jeans and 1200 t-shirts.

It is here that the pioneering work with FibreTrace occurs. David said he is most proud of this innovation as it can really change the way cotton is traded and sold around the world. Australian cotton is prized for being the whitest cotton but in the past, once a producer sends the bales off they have no control over what happens next. In most cases it is blended with inferior cotton products and sold off as Australian, even if it contains just 1% Aussie cotton. The profits are skimmed off by the traders and middlemen. Danielle, David’s wife has long been in the fashion industry, and after some bad experiences, they decided they could do something about it. David sourced some new technology and bought the patent from the inventor and now it is all coming to fruition.

The system works in a similar way to how bank notes are identified. The special ingredient is a mineral from a rare earth element. This is incorporated into a synthetic fibre that actually looks a little like cotton. The fibre is fed into a chopper (technical term!) and the fine particles are impregnated into the cotton fibre in tiny amounts. It’s like giving the cotton its own pedigree code that can be read at the other end of production – in the fashion houses and sellers around the world.

Good Earth Cotton is Danielle’s and David’s brand where their cotton is carbon positive (meaning Keytah is putting more carbon back into the soil that it is taking out to produce the cotton), contains FibreTrace technology that is environmentally sustainable, completing the chain from seed to shelf. David has applied to be a B Corp business and that looks like coming through very soon.

And that was what I learned on my day off the bike! David and Danielle don’t live on the property anymore. David had made a 6 hour drive to meet us – he normally flies his plane but that was being serviced. I am so appreciative that he made the effort to meet and show us around, with all the energy and passion of someone so proud of where this new business, in particular, is going and the difference it will make.

The size and scale of Keytah seems far removed from Margaret’s tree planting and biodiversity project on her 100 acre property (on Day 1), but the principal of taking care of the environment, as a temporary custodian of the land, and endeavouring to leave it in better condition than the land when they bought it – is just the same.

Moree to Bourke

7th-10th May

(Days 7-10)

Distance: 442km

Gavin, the filmmaker for the first week, flew out from Moree and for the next week it is just myself and Martin doing the filming before Morgan joins us after Bourke on 13th May.

After all the hill climbing of the first few days, from Moree to Bourke was almost deadpan flat. It was essentially slow and steady, hours on the saddle in one position, sometimes into a headwind, other times, the conditions were almost perfect for cycling. Riding over the good tarmac roads with the 4” wide fat bike tyres isn’t very efficient compared to using a touring or MTB, but my Christini was surprisingly nimble. I chose this bike to handle to worst of the conditions on my journey across Australia (the Simpson Desert for example) so this means foregoing some of the efficiency for the first 1400km.

The landscape was uniformly in good heart with a carpet of green grasses over the often parched landscape. The recent rains have brought the land to life, the roadside often lined with flowers and high grasses.

Getting some good distance under my belt over the first couple of days enabled me to take it a bit easier in Bourke. My body is ready for a break before I push myself into the ground. The cycling aim is to slowly pedal myself into form and covering more than 1000km in the first 9 days of cycling is right on the edge in these conditions.

Day 7

Moree (starting @Watercourse Road) to Collarenebri

129km

Day 8

Collarenebri to Walgett + 57km

137km

Day 9

Walgett + 57km camp to Brewarrina

78km

Day 10

Brewarrina to Bourke

98km

Map of the route so far

What an incredibly detailed and interesting post. I can’t believe that you can do this AND ride the distances that you do.

Great blog post Kate, really enjoying your commentary. And, by the way, HAPPY BIRTHDAY. We hope, celebrating your birthday, put an extra zest into your ride today. Happy & safe travels

You’ve given us a lovely present, yet it’s your birthday not ours.

Thanks for your educational insights on sustainable agriculture.

May you be able to enjoy a good red, and not run into any on the road!

happy birthday.

Thanks Kate … you’re covering impressive distances! Any mice? I read there is a terrible mouse plague in western NSW due to the excellent season. At least the mice don’t eat cotton!!

Nick

Happy birthday! Incredible adventure, keep the stories coming!

Great work so far, Kate! Inspiring to see Australians leading in the sustainability space. The irrigation system is really interesting. Thanks for sharing it all with us. Enjoy the flat tarmac cycling while it lasts!

Wow again Kate.

How on earth you manage to get all this incredibly interesting commentary done, and all those kilometres under your belt. is astounding. So admire your drive, pedal!

Wish your efforts and ethos could be more internationally broadcast. All the best.

Hi Kate, great story about Kaytah. Cheers, Phil